⚙ Atrium Research

✔ Problem & Solution

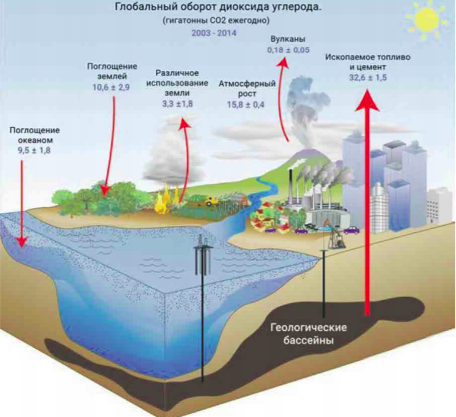

By 2050, carbon dioxide emissions must be reduced to zero. The economic incentive for this is the payment for CO2 emissions. In Europe, the fee has risen to 100 euros per 1 ton of CO2. Technologies have been developed to capture CO2 from the exhaust gases of coal-fired and gas-fired power plants. The best technologies capture CO2 at a cost of $57 per 1 ton. There are new solutions that promise to reduce costs to $39 per 1 ton, but this is not enough. The IPCC argues that costs should be reduced to $25-30 per tonne of avoided CO2 emissions. In the energy aspect, the cost of capturing CO2 is 10-30% of the capacity of thermal power plants. Such costs are unacceptable for developing countries and burdensome for consumers in general.

Atrium offers technology that zeros out the energy cost of capturing CO2. The patented method of burning carbon fuel increases the efficiency of thermal engines of power plants (gas turbine and reciprocating). The energy margin covers the cost of capturing CO2. The costs are reduced to depreciation costs and ongoing maintenance. Cost calculations for our method give values of 7 – 11 US dollars per 1 tonne of CO2. Possible margin – from 14 to 23 dollars per 1 ton of CO2.

The essence of the technical solution. The technology is an upgraded technology for capturing CO2 from exhaust gases, which was recommended by the IPCC in 2005. This technology from the IPCC increases the concentration of CO2 in exhaust gases, which reduces the cost of capturing CO2 many times over. Atrium offers a composition of the gas-fuel mixture, which reduces the energy consumption for compressing the gas-fuel mixture. In piston engines, the cost of compressing the mixture is reduced by 5-10 times. In gas turbine engines, energy costs are reduced by 5 times.

This is effective because, for example, the cost of operating an air compressor is 55-60% of the power of a gas turbine. Our method also solves the problem of reducing the cost of producing second-generation biofuels – algae and land plants. The technology ensures the combustion of fuel, in which the water content can reach 87% (combustion is carried out in oxygen, purified from nitrogen). Thus, the entire preparation of biofuel is limited to obtaining an aqueous suspension of fuel. At the same time, the problem of removing previously accumulated CO2 from the atmosphere and oceans is solved.

✔ Key Metrics Suggested Technology:

✓ Zeros the cost of capturing CO2;

✓ Gives additional energy gain, which increases profitability;

✓ Can be introduced through the modernization of existing equipment of power plants and ships;

✓ Solves the problem of inexpensive removal of CO2 from the exhaust gases of gas turbine plants, in which the proportion of CO2 is usually 3-5%;

✓ Enables combustion of highly moist fuels (with moisture content up to 87% by mass), which allows the use of biofuels (algae and wood flour) without expensive drying processes;

✓ Allows the use of low-calorie synthesis gas from coal gasification without loss of efficiency and RDF (Refuse Derived Fuel);

✓ The possibility of burning plastic waste in view of the possibility of complete accumulation in underground storages of exhaust gases containing dioxins (the decomposition time of dioxins is about 10 years).

ur method also solves the problem of reducing the cost of producing second-generation biofuels – algae and land plants. The technology ensures the combustion of fuel, in which the water content can reach 87% (combustion is carried out in oxygen, purified from nitrogen). Thus, the entire preparation of biofuel is limited to obtaining an aqueous suspension of fuel. At the same time, the problem of removing previously accumulated CO2 from the atmosphere and oceans is solved.

Capture of carbon dioxide in exhaust gas

Flue gases from thermal power plants, primarily coal-fired ones, are the main air pollutants. How to economically and efficiently remove carbon dioxide (CO2) from flue gases? – that is the question.

The concentration of CO2 in the smoke emissions of heat engines is quite low, and its separation is very expensive. If it is possible to reduce the cost of extracting it, then this technology will also solve the challenge set by the XPRIZE Carbon Remova competition – to extract carbon dioxide directly from the atmosphere.

Five Carbon Conquest Projects in Three Natural Elements

The article proposes the best options for the placement of complexes designed to remove CO2 from the atmosphere and oceans. Five ways are proposed to reduce energy costs for carbon dioxide capture, using the following factors: extreme currents in the oceans; steady storm winds; zones of low air temperatures, in which CO2 is in the state of ice; land plots in which the concentration of CO2 is hundreds of times higher than usual; river flows into the oceans, in which CO2 is highly concentrated. The proposed solutions increase the efficiency of carbon dioxide capture by tens and hundreds of times.

The stated concept is a platform for the consolidation of enthusiasts to participate in an international competition and attract investors for the manufacture of a demonstration plant, which should extract CO2 in the amount of 1 ton per day.